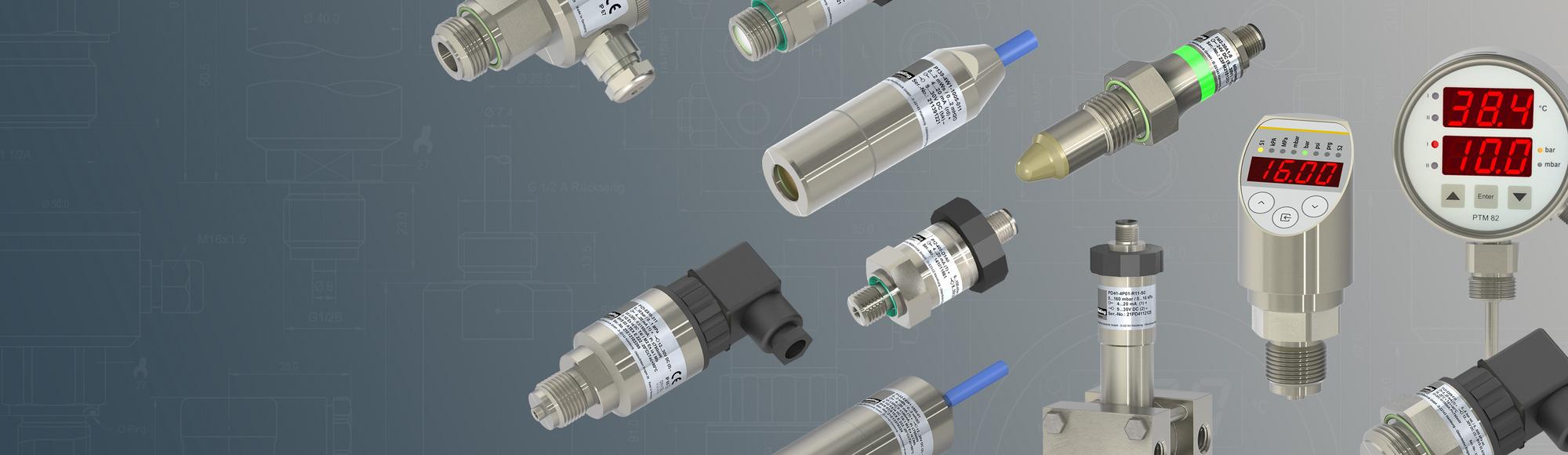

Your partner for pressure,

level and temperature

Scopes of application

General

Pressure and level monitoring are elementary components of plant monitoring and control across all industries. Liquid and gaseous media of all types are reliably measured. Nöding Messtechnik uses ceramic and metallic sensor elements to optimally adapt to the respective application.

Food industry

Special hygiene requirements and easy cleaning are the focus of this industry. Industry-specific process connections are often a core requirement. Nöding Messtechnik understands the requirements of this industry and offers hygienically designed devices that have been used in the food and beverage industry for decades.

Shipping

Harsh operating conditions and a variety of different ship configurations require precise knowledge of the respective application. Nöding Messtechnik has its origins in shipping, knows the industry very well and has been supplying dealers and shipping companies with pressure sensors and level sensors for ballast water tanks, fresh water tanks, oil tanks and much more for decades.

Machinery and plant engineering

From standard applications to specially adapted OEM solutions, Nöding Messtechnik supplies the most diverse areas of mechanical and plant engineering. The quantities of the customers range from 1-10,000 devices per year. We are very familiar with industry-specific conditions, due to our close customer contact.

Water / waste water

The water and wastewater management sectors require pressure and level sensors specially adapted to their needs. In water treatment and wastewater, the sensors frequently come into contact with a variety of different media. Nöding Messtechnik supplies sensors specially developed for these applications for optimal process reliability.

Oil and fuel

Oils and fuels have increased creep properties. In addition, the chemical resistance of the parts in contact with the media is the focus of these applications. Nöding Messtechnik supplies the industry with pressure transmitters and level transmitters specially designed to meet the requirements, in order to ensure a consistently high level of process reliability. ATEX approvals guarantee safe operation.

Chemicals

In this industry, chemical resistance is the focus of the applications and thus the right selection of the parts that come into contact with the media. A modular principle enables the customised combination of materials such as stainless steel, special elastomer seals and chemically resistant plastics. ATEX approvals guarantee use in potentially explosive atmospheres.

System supplier / intermediary

We maintain a very close partnership with our intermediaries and system suppliers, who are active in a wide range of industries. We are happy to work with you to find the right solution for your end customer. Short delivery times and fast support response times are a matter of course. Contact us!

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/4/c/csm_Website_8cff05746c.jpg)